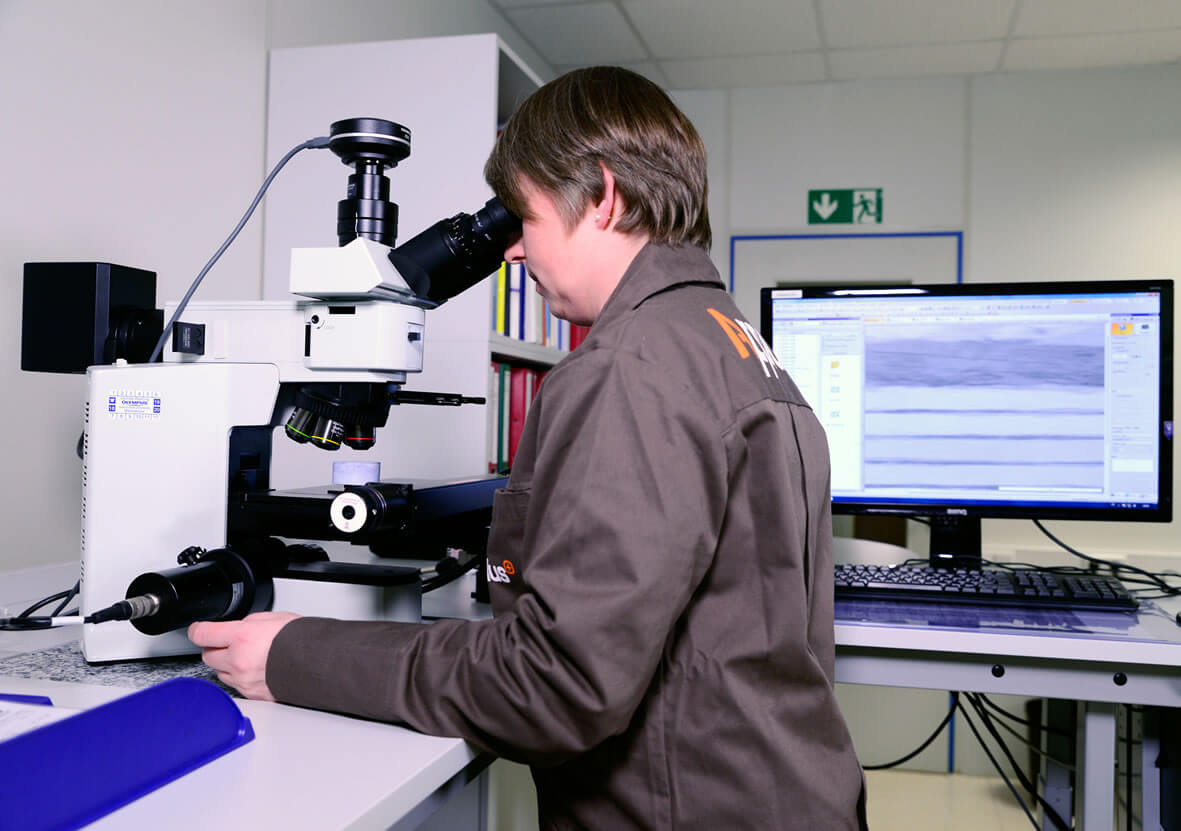

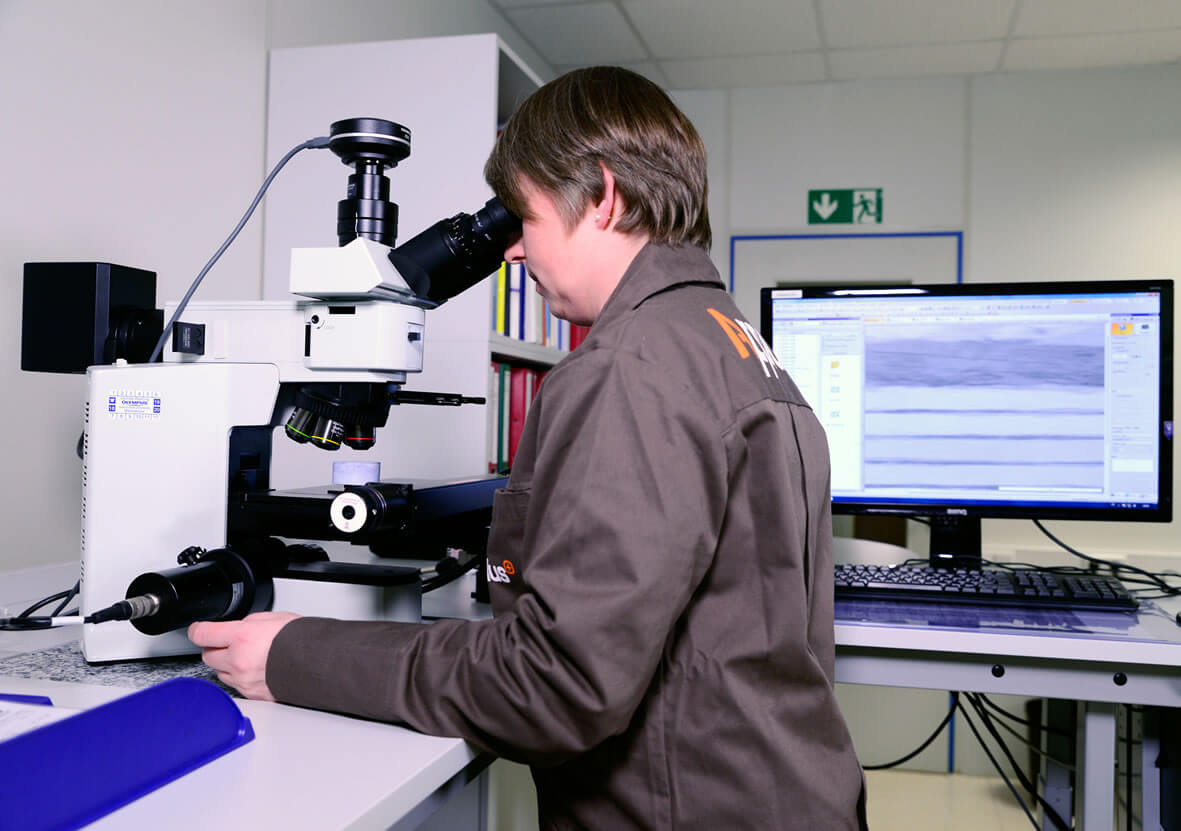

Metallography testing is a critical process in material science used to analyze the microstructure and properties of metals and alloys. This non-destructive or semi-destructive testing method provides insights into material characteristics like grain structure, phase distribution, inclusions, and surface treatments, ensuring product quality and performance. Below are the key aspects examined in metallography:

1. Microstructure Analysis : Microstructure examination reveals the arrangement of grains, phases, and defects in metals. It helps determine mechanical properties such as strength, toughness, and ductility.

2. Grain Size Measurement : Grain size influences a material's hardness and strength. Smaller grains typically enhance material strength (Hall-Petch relationship), while larger grains improve ductility. Grain size is measured using standards like ASTM E112.

3. Case Depth Measurement : For surface-hardened materials, case depth indicates the thickness of the hardened layer. It ensures proper wear resistance for components like gears and shafts.

4. Inclusion Analysis : Non-metallic inclusions, such as oxides or sulfides, can weaken a material. Inclusion analysis ensures purity and enhances performance in critical applications like aerospace and medical devices.

5. Decarburization Assessment : Decarb testing measures carbon loss from the surface due to heat treatment. Excessive decarburization reduces surface hardness and wear resistance.

6. Plating Thickness : Measuring the thickness of protective coatings ensures durability and corrosion resistance in harsh environments.

7. Welding Penetration :

Welding penetration analysis evaluates the depth of fusion in welded joints, ensuring structural integrity.